At Peterson Cat, safety is the foundation of our business: we make it a non-stop focus, so we can go home without incident or injury every day. This means that we don’t stop thinking about safety—period.

Working safely benefits our employees, our customers, and our bottom line, so we’ve implemented the following guidelines, rules, and practices to promote it.

Request Safety Information

We obey the laws. Peterson’s technicians research and abide by the regulations that govern your business before we set foot on your site. We stay up-to-date with the latest guidelines, rulings, and best practices from the following regulatory organizations:

- Occupational Safety and Health Administration - General Industry, Construction, and Maritime (OSHA)

- National Fire Protection Association (NFPA)

- U.S. Environmental Protection Agency (EPA)

- Federal Motor Carrier Safety Administration (FMCSA)

- Mine Safety & Health Administration (MSHA)

- Oregon Occupational Safety and Health (Oregon OSHA)

- California Division of Occupational Safety and Health (Cal/OSHA)

- Washington Occupational Safety and Health Division (Washington OSH)

We follow industry-specific best practices. Every industry we serve is different, therefore jobsite safety requirements can differ. In order to serve our customers and our wide range of industries, we train all Peterson technicians on the specific requirements of industries like:

- Mining and quarry

- Residential construction

- Heavy construction

- Paving & compaction

- Waste management

- Scrap & demolition

- Government facilities

- Forestry

We obtain proper safety training from licensed providers. Peterson’s team of technicians must demonstrate mastery of an extensive safety curriculum in addition to the technical training they receive on Cat and other brands of equipment. Here are some of the certifications Peterson employees must complete:

- NFPA 70e Training (Workplace Safety Solutions, Inc.)

- Shipyard Competent Person Training (West Coast Marine Chemists, Inc.)

- OSHA training (Caterpillar, Inc.)

- TWIC credentials (TSA)

- CPR/First Aid/AED certifications (Red Cross)

- Mobile Elevated Work Platforms (Genie)

- MSHA – New Miner Training part 46 & 48 / Annual Refresher Training (Vivid)

- ATEM – American Trauma Event Management

- Commercial Driver Qualifications

- SPCC and HazMat Awareness Training (Caterpillar, Inc.)

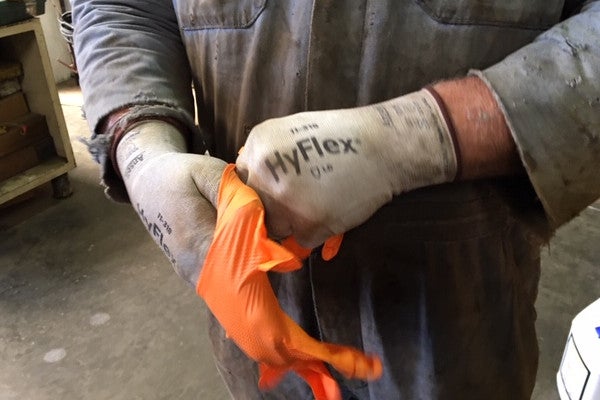

We use the appropriate gear. In addition to following the various rules and regulations governing your specific industry, Peterson’s technicians are also trained and equipped with the safety gear and personal protection equipment appropriate to your workplace, including:

- Eye/face protection

- Hand protection (cut level 2 minimum)

- Fall protection

- Hearing protection

- Arc flash protection

- Foot protection

- Head protection

- Welding

- Fire prevention and suppression equipment

Safety is part of our culture. At Peterson, safety is the foundation of our core values. We have integrated specific programs and practices into our daily lives to ensure safety is a reflexive part of our culture:

- Peterson’s full-time safety team investigates all incidents, including near-misses

- Weekly recap of all safety incidents, near misses, and good catches

- Weekly tailgate trainings

- Safety stand downs following potential serious incidents

- Job hazard analysis (JHAs) performed on all projects

- Workplace inspections performed at MSHA sites

- Quarterly safety reviews conducted for all locations

- Peer-to-peer training and mentoring programs, including one-on-one safety coaching/recognition

- Compliant ISN/Avetta/Browz members (third-party safety statistic organizations required by many customers)

- Daily vehicle inspections per DOT requirements

Want to know more about safety at Peterson Cat? Complete this form or get in touch with your product support representative.

WARNING

WARNING