Rubber Track Special

UP TO 50% OFF CAT RUBBER TRACKS

Until December 31, Peterson Cat is offering big discounts on Genuine Cat rubber tracks, with a special incentive when you buy online.

Cat Advansys Adapters

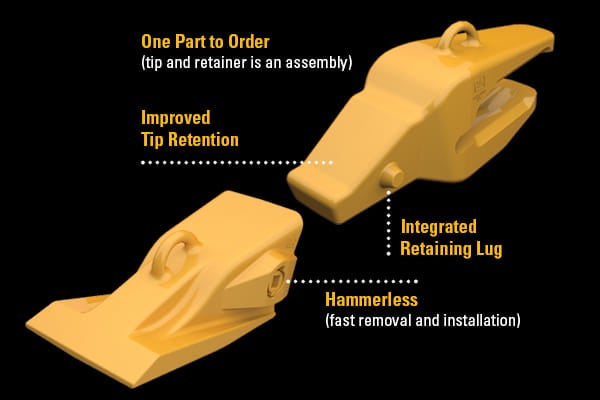

CAT ADVANSYS SYSTEM BENEFITS SUMMARY:

- Improved Productivity: Exclusive tip and adapter features result in the highest productivity Cat system

- Enhanced Reliability: Strongest, most robust adapters Caterpillar® has ever produced

- Hammerless Installation: Quickest hammerless tip removal and installation with a 3/4 inch retainer lock that requires no special tools

- Simplify Installation: Integrated retention components mean no more searching for pins or retainers

- Simplify Retrofitting: Easy upgrading because Advansys adapters drop into the same space as K series

- Simplify Ordering: One part number to order when changing a set of tips

CAT ADVANSYS SYSTEM PERFORMANCE:

- Exclusive performance features such as tapered tip sides offer less drag and higher productivity

- New and optimized tip shapes put wear material where you need it most

CAT ADVANSYS SYSTEM RELIABILITY:

- Stronger adapter noses are designed with up to a 50% stress reduction

- Improved adapter nose geometry reduces sliding wear on adapter nose surfaces extending the life of the adapter

- Improved tip shapes shadow the adapter straps and welds for longer adapter life

- Top covers available for double strap adapters and full adapter covers available for high abrasion flush mount adapters

CAT ADVANSYS HAMMERLESS INSTALLATION AND REMOVAL:

- Half turn of retention locks and unlocks the CapSure retention

- Only a 1/2” or 3/4” breaker bar is required to change the tips

- Retention components come installed in tips

Cat Advansys for Wheel Loaders

Contact Us

Heavy Abrasion

- Use in easy to penetrate high abrasive materials

- Lower penetration ability

- Heavy wear pad for long wear life

Heavy Penetration

- Use in hard to penetrate high abrasive materials

- Very good penetration

- Heavy wear pad for long wear life

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Loader

- Use in low abrasive materials

- Good penetration

- Single top self-sharpening cavity

Coal

- Use in low abrasive materials like coal seams

- Use on loaders to produce a smoother floor

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Cat Advansys for Excavators

Contact Us

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Excavator

- Use in low abrasive materials

- Good penetration

- Single top-self-sharpening cavity

Wide

- Use on excavators to produce a smoother floor

- Reduced penetration

- Less bucket spillage between tips

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Spike

- Use in very hard to penetrate, low abrasive materials

- Maximum penetration

- Cross section to maintain sharpness

Double Spike

- Use in hard to penetrate, fracturable materials

- Excellent penetration

- Use at corner positions with spike centers

WARNING

WARNING