Cat Advansys Adapters

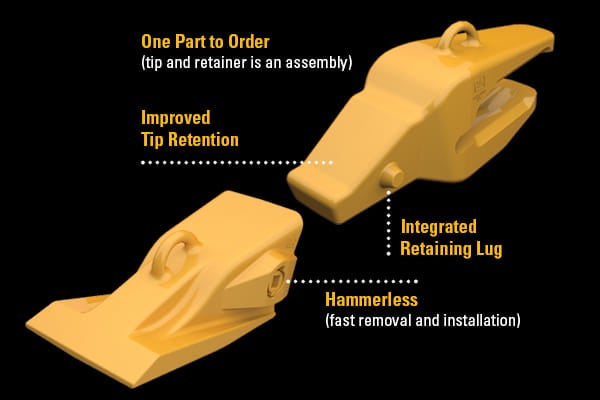

CAT ADVANSYS SYSTEM BENEFITS SUMMARY:

- Improved Productivity: Exclusive tip and adapter features result in the highest productivity Cat system

- Enhanced Reliability: Strongest, most robust adapters Caterpillar® has ever produced

- Hammerless Installation: Quickest hammerless tip removal and installation with a 3/4 inch retainer lock that requires no special tools

- Simplify Installation: Integrated retention components mean no more searching for pins or retainers

- Simplify Retrofitting: Easy upgrading because Advansys adapters drop into the same space as K series

- Simplify Ordering: One part number to order when changing a set of tips

CAT ADVANSYS SYSTEM PERFORMANCE:

- Exclusive performance features such as tapered tip sides offer less drag and higher productivity

- New and optimized tip shapes put wear material where you need it most

CAT ADVANSYS SYSTEM RELIABILITY:

- Stronger adapter noses are designed with up to a 50% stress reduction

- Improved adapter nose geometry reduces sliding wear on adapter nose surfaces extending the life of the adapter

- Improved tip shapes shadow the adapter straps and welds for longer adapter life

- Top covers available for double strap adapters and full adapter covers available for high abrasion flush mount adapters

CAT ADVANSYS HAMMERLESS INSTALLATION AND REMOVAL:

- Half turn of retention locks and unlocks the CapSure retention

- Only a 1/2” or 3/4” breaker bar is required to change the tips

- Retention components come installed in tips

Cat Advansys for Wheel Loaders

Contact Us

Heavy Abrasion

- Use in easy to penetrate high abrasive materials

- Lower penetration ability

- Heavy wear pad for long wear life

Heavy Penetration

- Use in hard to penetrate high abrasive materials

- Very good penetration

- Heavy wear pad for long wear life

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Loader

- Use in low abrasive materials

- Good penetration

- Single top self-sharpening cavity

Coal

- Use in low abrasive materials like coal seams

- Use on loaders to produce a smoother floor

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Cat Advansys for Excavators

Contact Us

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Excavator

- Use in low abrasive materials

- Good penetration

- Single top-self-sharpening cavity

Wide

- Use on excavators to produce a smoother floor

- Reduced penetration

- Less bucket spillage between tips

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Spike

- Use in very hard to penetrate, low abrasive materials

- Maximum penetration

- Cross section to maintain sharpness

Double Spike

- Use in hard to penetrate, fracturable materials

- Excellent penetration

- Use at corner positions with spike centers

Power Shop Technician

Do you have extensive experience maintaining and repairing diesel engines? Would you enjoy the daily challenge of working on the most advanced power system equipment in the industry?

If so, a career as a power technician could be the perfect choice. Peterson Cat, a leading Cat® dealer in the Western U.S., has openings for skilled power technicians throughout California, Oregon, and southwest Washington. (Field power technician positions are also available.)

What Does a Power Shop Technician Do?

As a Cat power systems technician with Peterson Cat, you will work in our fully equipped power shop servicing Cat engines, power generation equipment, and related accessories:

- Preparation, setup, installation, and startup of marine generators, engines, and related machinery and equipment manufactured by Caterpillar, a widely recognized industry leader.

- Repairing, rebuilding, or replacing marine, industrial, and EPG engines and additional components from Caterpillar and other top brands.

- Servicing Level 1 and Level 2 generator systems.

- Performing equipment inspections as needed.

- Supporting the efforts of electric power technicians in the field as needed.

What Does It Take to Be a Peterson Cat Equipment Repair Technician?

To qualify for the power shop technician role at Peterson Cat, you should have an associate degree in diesel technology or a closely related field of study from an accredited academic or technical/vocational institution. Successful applicants also have at least five years of engine service or power generation work experience. We will also consider an equivalent combination of education and work experience.

Why Consider This Position?

As a power system technician, you will have the immense satisfaction of being a hero to our valued customers who depend on your expert services to get their essential equipment engines back on the job and productive. You'll have more than a career — you'll also have a purpose.

We recognize that talented and exceptionally motivated individuals like you have high expectations. We acknowledge your outstanding skills and strong desire to succeed by providing generous wages, competitive fringe benefits, and exciting promotional opportunities with our power system technician jobs.

What Are the Advantages of Working With Peterson Cat?

At Peterson Cat, we're proud of our family-oriented work environment, which focuses on safety, winning, growth, and professional achievement. You'll be more than just an employee — you'll be a valued member of an organization that genuinely cares about your current and future success.

Recruiting and training the best people is critical for fulfilling our company's mission. We have high standards for a good reason: Our team represents Peterson Cat, our family, our brand, and our values.

Apply Today

Kick your career into high gear by becoming a Peterson Cat power shop technician. Take the next step and complete the online application today. You can also explore our heavy equipment mechanic jobs located throughout our operating territory.

Peterson Power Systems, Inc. is committed to equal employment opportunity and affirmative action. Minorities, females, veterans, and individuals with disabilities are encouraged to apply. A drug screen and background check are required.

WARNING

WARNING