Free Undercarriage Inspection

Plus 0% Interest for 36 Months* (equal payments with no payments for the first 6 months). $3,500 minimum purchase.

Undercarriage Choices for Construction

Whether you’re clearing a site, digging a basement, or doing landscaping, the undercarriage on your construction machines are critical to production speed, flotation, and stability. Cat undercarriage options include complete systems as well as individual components designed to make a difference in your operation.

Undercarriage Options for Cat Dozers

- General Duty (GD)

- Heavy Duty (HD)

- Heavy Duty XL (HDXL)

- Cat Abrasion™

Undercarriage Options for Cat Excavators

- General Duty (GD)

- Heavy Duty (HD)

- Heavy Duty XL (HDXL)

Steel Track Undercarriage

The Difference

The only OEM that has been designing and building undercarriage for more than 100 years.

The Proof

With the right operating technique and proper maintenance, you can lengthen the track life of your machine.

The Design

Designed to work and wear as a system, every component meets strict Caterpillar specifications and quality standards to offer lasting performance.

The Decision

With long wear life and lower total cost of ownership, Cat undercarriage deliver for your jobsite needs. Talk with Peterson Cat to find the type of steel track undercarriage best matched to your operation.

Rubber Track Undercarriage

The Difference

Cat undercarriage are engineered to provide traction in dynamic environments, helping you maneuver around tight quarters with minimal ground disturbance.

The Proof

Factory- and field-tested, Cat rubber track undercarriage offer a longer lasting life than major competitors.

The Design

Designed for increased performance and longevity, Cat rubber track undercarriage are available in multiple tread patterns so you can pick what works best for your typical operation.

The Decision

With a long wear life and lower total cost, Cat undercarriage deliver the best return on your investment. Let Peterson Cat help you choose the best rubber track undercarriage for your machine.

Field Testing

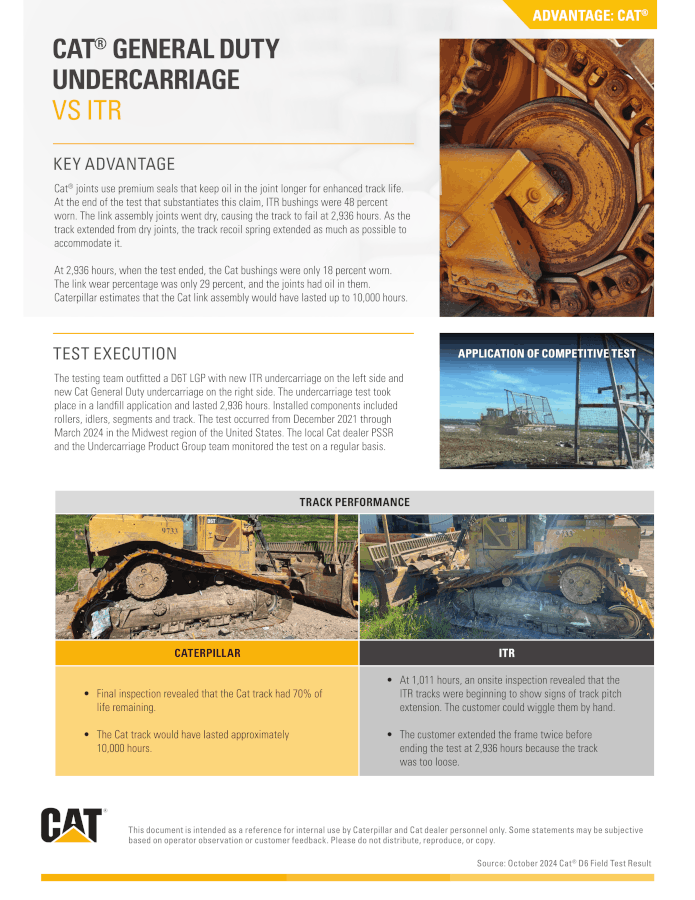

Cat General Duty Undercarriage vs ITR

Test Execution:

The testing ream outfitted a D6T LGP with new ITR undercarriage on the left side and new Cat General Duty undercarriage on the right side.

The undercarriage test took place in a landfill application and lasted 2,936 hours.

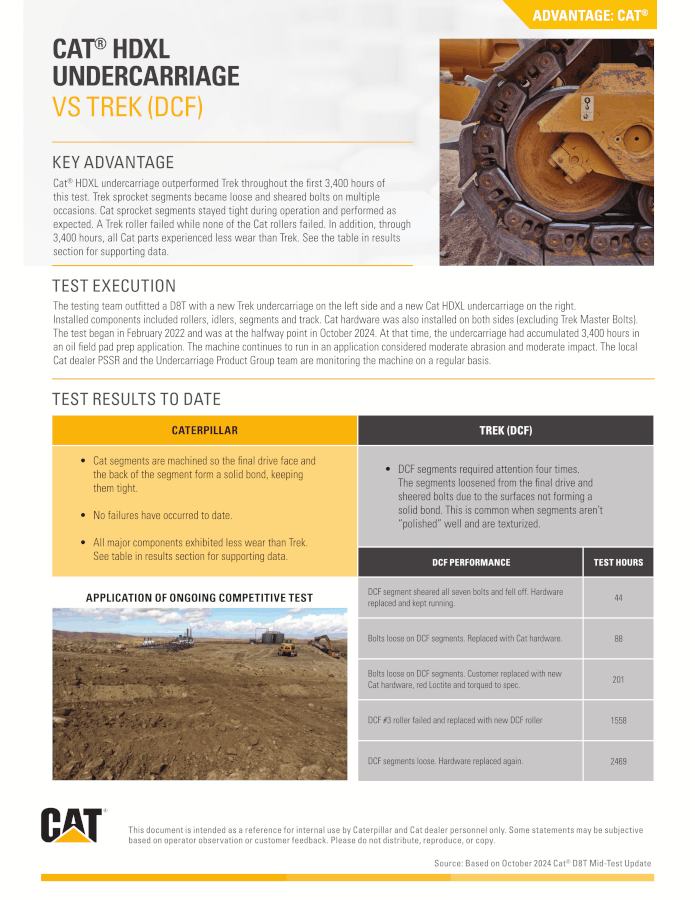

Cat HDXL Undercarriage vs Trek (DCF)

Test Execution:

The testing team outfitted a new D8T with a new Trek undercarriage on the left side and a new Cat HDXL undercarriage on the right.

The test began in in February of 2022 and was at the halfway point in October 2024.

How to Extend the Life of an Undercarriage

The most expensive part on a tracked dozer or excavator is the undercarriage, representing 50% of the machine’s owning and operating costs. Proper use of the machine can extend the life of the undercarriage.

Side-hill operation can accelerate wear on the links on one side when overused.

Avoid unnecessary reverse operation. It wears the bushings and sprockets.

Check the track alignment. When tracks are not properly aligned it can cause component wear.

Minimize sharp turns and counter rotations, as these maneuvers stress the tracks from brake use on one side or the other.

Slipping the track can cause premature wear on components and the track itself. It also reduces production and increases fuel consumption.

Keep the right track tension. Adjust and test the track tension as needed. Tight tracks can increase wear on bushings, sprockets, links and idlers. Too tight of tracks can increase wear and strain.

Choose the right shoes for the job. Using the wrong shoe width can increase wear and strain on links, pins, and bushings.

Keep the undercarriage clean. Materials and debris can build up, especially in certain climates and depending on what type of material the machine is working in.

Avoid high speed tracking, as it elevates track temperatures too high and causes premature wear.

Video Library

When to Replace Cat Rubber Tracks on Compact Loaders

How to Choose Steel Tracks for Cat Small Dozers

How to Choose Steel Tracks for Cat Large Excavators

How to Choose Steel Tracks for Cat Medium Dozers and Track Loaders

How To Choose Steel Tracks For Cat Small Excavators

How to Choose Steel Tracks for Cat Medium Excavators

WARNING

WARNING