Earthmoving Technician

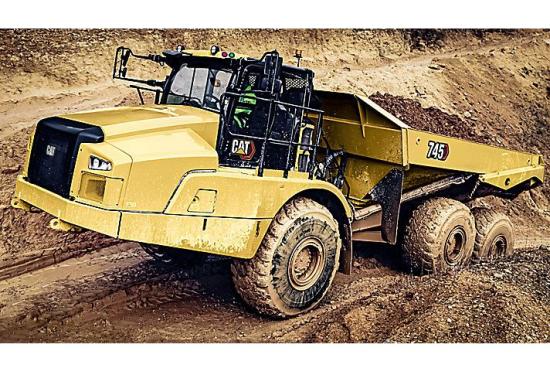

Earthmoving mechanics ensure that the dozers, excavators, and loaders never stop running. Peterson Cat is seeking technicians who are skilled in repairing diesel engines and diagnosing mechanical issues in heavy equipment. We have jobs available across our network of full-service locations in Northern California, Oregon, and southwest Washington.

We are a locally rooted, multigenerational family business, and we believe that diesel technicians are essential to the economy, whether they work at a shop in a big city or provide emergency repairs on a rural jobsite. Our team of technicians has the modern diagnostic tools, manufacturer training, and support they need to do superior work and grow a long-term career with a worldwide leader.

Two Career Paths, One Essential Role

An earthmoving career at Peterson Cat involves hands-on repair and service for various sizes and configurations of earthmoving equipment. Work is primarily done with Cat® equipment, but also includes repairing equipment from other manufacturers. Core responsibilities will vary depending on the career path type.

In-Shop Technicians

In-shop equipment service technicians work from our locations and have access to specialized equipment like overhead cranes and heavy tooling. Work includes hands-on repair of engines, transmissions, hydraulic systems, electrical components, and more.

Some of the primary responsibilities for this role include:

- Diagnose earthmoving equipment

- Rebuild critical components and systems

- Write clear service documentation and work orders

- Complete predelivery setups for new equipment

Field Service Technicians

On-site heavy equipment service technician jobs are about delivering service and repair solutions to our customers' facilities or other remote locations. You will interact directly with clients and work from a service truck equipped for repairing bulldozers, excavators, motor graders, and other heavy machines.

Some of the primary responsibilities for this role include:

- Onsite troubleshooting

- Write detailed service reports

- Emergency repair, rebuild, and replacement

- Perform service in a timely and efficient manner

Qualifications of Our Equipment Service Technicians

We consider candidates with a minimum of five years of relevant experience in heavy equipment diagnostics, troubleshooting, and repair, especially with Cat products. An associate degree in diesel technology or a related field is preferable, but a combination of equivalent education and hands-on experience is also acceptable.

You will need to maintain a valid driver's license and a satisfactory driving record to be eligible for the job. We require a background check and drug screen for each position.

Why Join the Peterson Cat Team?

At Peterson Cat, we believe that our technicians are lifesavers for customers, minimizing downtime and protecting their investments with quality service and repair. With a territory spanning 100,000 square miles, we have the resources to invest in each team member, providing training, workforce development, competitive pay, employee benefits, and opportunities for advancement.

Ready to Build Your Service Technician Career?

At Peterson Cat, we provide equal employment opportunities for skilled technicians. We welcome minorities, females, veterans, and individuals with disabilities to apply. Explore available opportunities across the region and take your career to the next level.

Specials

Machine Financing Specials

50% OFF LIST RENTAL RATES

on ALL daily and weekly rents from February 1 – 28, 2026 with promo code FEB50

0% for 60 months

on new skid steers, compact track loaders, mini & micro excavators, and compact wheel loaders.

0% for 36 months

on new backhoe loaders, small wheel loaders, small dozers, and telehandlers.

0% for 36 Months + CVA and EPP

on new 313-390 excavators includes Forestry Models!

0% for 36 Months + CVA

on new articulated trucks + small, medium, large and wheeled excavators.

3.99% for 48 Months + CVA

on new medium dozers, medium wheel loaders, track loaders, motor graders and soil compactors

0% for 18 Months

on qualifying Cat work tool attachments: augers, brooms, hammers, mulchers, and more!

Need help finding the best deal or selling your machine?

Contact us to discuss new, used, lease, and consignment options.

Parts & Service Specials

0% for 36 Months with no payments for the first 6 months

on new and Cat Reman parts, with or without service. $3,500 minimum purchase.

Undercarriage Offer

Free inspection, 0% for 36 months, and no payments for 6 months. $3,500 minimum purchase.

30% Off Cat Grader Cutting Edges

Discounts on select Cat grader cutting edges from Peterson Cat with Code: GRADER30

plus get 0% financing for 36 months (with no payments for six months) when you use your Cat Card account

15% off Oil & Grease

Discounts on select genuine Cat oil & grease from Peterson Cat with Code: CATEX25

20% off Edges & Teeth

Bucket/blade cutting edges, base edges, and teeth with Code: GET20

25% off Filters

Discounts on select Cat oil, air, and fuel filters with Code: FLT25

20% off Hoses & Couplings

Discounts on hose & coupling piece parts and assemblies with Code: HYD20

Want to manage your machines online?

Our eCustomer Support Team is happy to take your call, help you set up an account, and provide training.

Electric Power Technician

Peterson Cat is hiring experienced power technicians throughout California, Oregon, and Southwest Washington to work on Cat® engines, generators, power systems, and other components. These positions require expertise in the repair of power generation equipment for industrial, marine, and emergency power applications.

The Role of Power Generation Technicians at Peterson Cat

The job centers on Cat engines and power generation systems — diesel and natural gas generators that provide backup power for hospitals, data centers, marine vessels, and a wide range of other applications. You need mechanical skills to rebuild engines and electrical knowledge to service generator systems.

Core responsibilities include:

- Installing and commissioning equipment: Set up new generators, marine engines, and power systems according to manufacturer specifications and verify they're ready for operation.

- Repairing and rebuilding engines: Disassemble, diagnose, and restore Cat and non-Cat engines used in power generation, industrial, and marine settings.

- Performing electrical service: Conduct generator system maintenance.

- Maintaining accurate records: Document all service work clearly so that the team and clients stay informed about the equipment's status and the repairs completed.

- Adhering to quality and safety standards: Follow manufacturer specifications and safety protocols to ensure every job meets industry standards for quality and safety.

Qualifications of Our Power Generation Specialists

Candidates need at least five years of hands-on experience with diesel engines or power generation systems. An associate degree in diesel technology or a related technical field is preferred, although an equivalent combination of education and work experience also qualifies. We also require a valid driver's license and a clean driving record.

Career Paths for Critical Power Technicians

Peterson Cat offers two different career tracks for power technicians. Power shop technicians work in our fully equipped facilities, handling repairs, installations, and pre-delivery inspections in a controlled environment. Power field technicians travel to various locations in the field to perform on-site service, installations, and emergency repairs. Both paths offer competitive pay and room for advancement as you develop your skills.

Why Work as a Power Technician at Peterson Cat?

Peterson Cat is a family-owned business, meaning we operate differently from most corporate chains. We take a personalized approach with everything we do, including our employees, clients, and suppliers. We hire skilled technicians and invest in their development through training, workforce development, competitive pay, employee benefits, and opportunities for advancement.

We build our work environment on safety, superior quality, and getting the job done right the first time. Our team trains technicians on the latest Cat equipment and diagnostic technology. We also typically promote from within before seeking external candidates.

Apply for an Electrical Power Technician Position Today

Are you ready to apply your knowledge of diesel engines and power generation? Explore our available power technician positions and apply online today.

At Peterson Cat, we are committed to providing equal employment opportunities and promoting affirmative action. Minorities, females, veterans, and individuals with disabilities are encouraged to apply. We require a background check and drug screen for each position.

Earthmoving Shop Technician Jobs | CAT Equipment Repair

If you know how to repair a diesel engine and diagnose mechanical issues in heavy equipment, Peterson Cat wants you on our team. We're hiring shop technicians who can handle everything from bulldozers and excavators to skid steers and backhoe loaders. More importantly, we're committed to investing in your long-term career growth with a worldwide leader.

Our shop technicians work in state-of-the-art facilities throughout California, Oregon, and Washington. You'll have access to modern diagnostic tools, manufacturer training, and the support you need to do quality work on equipment from Caterpillar and other leading manufacturers.

The Role of the Earthmoving Shop Technician

The technician's workday involves hands-on repair of engines, transmissions, hydraulic systems, electrical components, and more. You'll also be responsible for rebuilding critical systems and preparing new machines for clients. Other primary responsibilities include:

- Diagnosing equipment malfunctions: Troubleshoot issues with various sizes and configurations of earthmoving equipment to determine the correct repair approach.

- Rebuilding critical systems: Disassemble, repair, and replace equipment components and systems.

- Documenting your work: Write clear service reports and prepare work orders that help the entire team stay informed and efficient.

- Following quality standards: Use manufacturer guidelines to perform each task correctly and keep accurate equipment records.

- Completing pre-delivery setups: Get new equipment ready for clients by performing thorough inspections, testing electrical and hydraulic systems, installing machine accessories, and topping off fluid levels.

- Prioritizing workplace safety: Maintain a safe working environment by observing all safety procedures, wearing required personal protective equipment, and identifying potential hazards.

Shop Technician Qualifications

We're seeking candidates with a minimum of five years of experience in heavy equipment diagnostics, troubleshooting, and repair. An associate's degree in diesel technology or a related field is preferred, but an equivalent combination of education and hands-on experience is also acceptable. You'll need to maintain a valid driver's license and a satisfactory driving record.

Why Choose a Career With Us as an Earthmoving Equipment Repair Specialist?

As an employee of Peterson Cat, you'll earn competitive hourly rates and benefits that support your life outside of work. We invest in continuous training, allowing you to work with advanced tools and stay current with the latest technology. As one of the largest Cat® dealers in North America, we have the resources to provide you with genuine opportunities for advancement.

We're a family-owned and operated business, meaning we run things differently from corporate chains. Our culture is built on safety, treating people right, and helping you grow professionally. Your daily responsibilities also matter — the equipment you service builds the roads, bridges, and infrastructure that keep communities across the country running smoothly.

We also offer numerous opportunities for advancement. People build long-term careers here because we typically promote from within and value the expertise you bring to the job.

Apply for the Shop Technician Job Today

Take the next step in your career by applying for a heavy machinery technician position with Peterson Cat. You can also browse the other spots we have open across the region.

Peterson Cat is committed to affirmative action and equal employment opportunities. Minorities, females, veterans, and individuals with disabilities are encouraged to apply. A drug screen and background check are required.

WARNING

WARNING